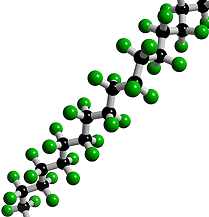

A common method used to obtain cellulosic fibers is alkalinization with NaOH. Depending on NaOH content, treatments remove significant quantities of lignin and hemicellulose as small molecules. In biorefineries, where the preservation of components is needed, KOH may prevent hemicellulose chain formation. Here, we studied the efficacy of obtaining cellulosic fibers from jute using KOH. Jute fibers are about 84.2% holocellulose, which corresponds to 59.5% alpha cellulose and 24.7% hemicellulose. To obtain high cellulosic fiber yields from jute, effects of pulping with different KOH concentrations and altering reaction times were studied using factorial planning (22). Afterward, in natura and treated fibers were characterized via Fourier transform infrared spectroscopy (FTIR), thermogravimetry (TG) and derivative thermogravimetry. Holocellulose sample components were obtained by removing lignin. Factors including concentration and reaction time individually significantly affected cellulose yield. Alpha cellulose was produced when higher levels of the factorial planning conditions were applied. Ideal parameters for cellulose extraction included the addition of 10% (w/v) KOH for 3 h. FTIR analysis was used to ensure that lignocellulosic components were removed by fiber treatment. TG showed that treated fibers were thermally stable at temperatures close to, or higher than, in natura fibers.

Doutoranda, Mestra